PRODUCT HIGHLIGHTS 2026

IFAM INTRONIKA ROBOTICS SLOVENIA

Razstavni prostor A-000

Inteligentni krmilnik, ki komunicira s tiskalnimi glavami, za tisk uporablja kartuše; ne koristi make-up, redčila, čistila. Tiska v resoluciji do 900 dpi; HP, Trident in Lexmark tiskalne glave; spomin 512 MB ali 1G flash, 128 MB RAM, 32 bitni data bus; 5,7” touch display s tipkovnico; I/O konektor, Interface, paralelni ethernet, vodenje preko PC.

Področja uporabe:

Direktni tisk na porozne, pol-porozne materiale ter tudi nekatere neporozne površin. Tiskalnik ima lahko nameščeno do 4 tiskalne glave; omogoča sočasno delovanje na dveh transportnih linijah; možna montaža tiskalnih glav eno nad drugo in s tem višji napis; mogoče ga je namestiti na steno, postaviti na mizo ali integrirati neposredno v proizvodno linijo.

Booth A-000

An intelligent controller that communicates with printheads; uses ink cartridges, no need for make-up, solvents or cleaners. Print resolution of up to 900 dpi; HP, Trident, and Lexmark printheads; 512 MB or 1G flash memory, 128 MB RAM, 32-bit data bus; 5.7” touch display with keyboard; I/O connector, Interface, parallel Ethernet, PC control.

Fields of application:

Direct printing on porous, semi-porous and also some non-porous surfaces. The printer can have up to 4 print heads installed; allows simultaneous operation on two production lines; possible installation of print heads one above the other.

Booth A2-400

One of the latest innovations we want to highlight is ELPEGUARD® Sharp Edge Protection (SEP) -developed to solve a common challenge in conformal coating: edge loss. Due to the natural flow behaviour of thin coatings, edges and tips (e.g., component leads and solder pins) may receive a thinner coating than flat surfaces, leaving sensitive areas less protected. (peters.de)

SEP helps increase edge coverage and insulation performance, improving protection against moisture and contamination, and extending electronics lifetime—both in standard applications (up to 100 V) and high-voltage applications (up to 1000 V).

Peters offers three practical routes to achieve improved edge coverage:

- SEP-modified coatings (acrylic and synthetic rubber systems)

- Higher layer thickness by optimizing application parameters

- Gels for critical areas, e.g., for solder pins

Razstavni prostor: A-500, A-401

Delovna postaja FAIRINO CNC je rešitev na ključ, zasnovana za poenostavitev avtomatizacije v industriji CNC. Z združevanjem robustnega ogrodja delovne postaje, polic s predali brezhibno integracijo s kolaborativnimi roboti FAIRINO pospešuje nastavitev in zagotavlja zanesljivo delovanje. Sistem podpira enostavno programiranje, hitro uvajanje in visoke varnostne standarde, kar proizvajalcem pomaga povečati fleksibilnost proizvodnje in se hitro prilagoditi spreminjajočim se zahtevam.

Področja uporabe: Delovna postaja, optimizirana za ponavljajoče se CNC nalaganje in razkladanje več delov, združuje kompaktno zasnovo z vzdržljivo konstrukcijo, zaradi česar je idealna za industrijsko uporabo.

Booths A-500, A-401

The FAIRINO CNC Workstation is a turnkey solution designed to simplify automation in the CNC industry. By combining a robust

workstation frame, drawer shelves for parts handling, and seamless integration with FAIRINO collaborative robots, it accelerates

setup and ensures reliable operation. The system supports easy programming, fast deployment, and high safety standards,

helping manufacturers increase production flexibility and adapt quickly to changing demands.

Fields of application: Optimized for repetitive CNC loading and unloading of multiple parts, the workstation combines a compact footprint with durable construction, making it ideal for industrial applications.

Razstavni prostor A-301A

Demonstracijski ventilator prikazuje, kako enostavno je mogoče obstoječe stroje nadgraditi z brezžično diagnostiko. S preprostim Bluetooth vtičem se podatki o vibracijah in stanju motorja neposredno prenašajo v moneo, kar omogoča takojšen vpogled v delovanje in obrabo. Brez ponovnega ožičenja, brez izpadov – takojšen dostop do gibanj, temperaturnih odstopanj in nastajajočih težav. Primer kako je mogoče tudi najosnovnejšo opremo preoblikovati v povezano, inteligentno opremo.

Področja uporabe: Živilska industrija, čiščenje voda in odpadnih voda, kemična industrija

Booth A-301A

Fan demonstrator shows how easily existing machines can be upgraded with wireless diagnostics. With a simple Bluetooth Plug, vibration and motor condition data stream directly into moneo, offering immediate insights into performance and wear. No rewiring, no downtime–just instant access to trends, temperature deviations and emerging issues. A practical example of how even the most basic equipment can be transformed into connected, intelligent assets.

Fields of application: Vibrations

Razstavni prostor A-301A

Ta hidravlični sistem omogoča digitalno spremljanje stanja s pomočjo podatkov senzorjev v realnem času: vibracije, pretok, tlak in temperatura. Oglejte si kako moneo zazna anomalije, še preden se pojavijo okvare. Simulirane napake prikazujejo, kako prediktivni modeli identificirajo neobičajno delovanje in sprožijo zgodnja opozorila. Rezultat je jasna ilustracija sodobnega vzdrževanja: manj zastojev, boljše načrtovanje in pametnejše razumevanje stanja strojev.

Področja uporabe: Hidravlika

Booth A-301A

This hydraulic system brings digital condition monitoring to life. Through live sensor data – vibration, flow, pressure and temperature – see how moneo detects anomalies long before they become failures. Simulated faults demonstrate how predictive models identify unusual behavior and trigger early warnings. The result is a clear illustration of modern maintenance: fewer stoppages, better planning and a smarter understanding of machine health.

Fields of application: Hydraulics

Razstavni prostor A-301A

Merilniki pretoka – celovit prikaz različnih tehnologij merjenja pretoka. To so ultrazvočne, magnetno-induktivne, vrtinčne in toplotne. Omogoča neposredno primerjavo med načeli delovanja, odzivnim obnašanjem in idealnimi področji uporabe.

Področja uporabe: živilska industrija, čiščenje voda in odpadnih voda, kemična industrija

Booth A-301A

Flow meters comprehensive display of different flow measurement technologies such as ultrasonic, magnetic-inductive, vortex and thermal. It allows direct comparison between principles, response behavior and ideal application areas.

Fields of application: Food and Beverage, Water and Wastewater Treatment, Chemical Industry

Razstavni prostor A-301A

Higienski procesni senzorji, ki so skladni z zahtevami EHEDG, FDA in CIP/SIP. Predstavlja celotno paleto senzorjev za merjenje tlaka, temperature, nivoja in pretoka v aplikacijah za živila in pijače. Poudarja higiensko zasnovo, različne priključke za sanitarna procesna okolja, stabilne in natančne meritve, ki so primerne za mlekarne, polnilne linije, pivovarne in druge procese v industriji živil in pijač.

Področja uporabe: živilska industrija

Booth A-301A

Hygienic process sensors compliant with EHEDG, FDA and CIP/SIP requirements. It showcases a complete range of sensors for pressure, temperature, level and flow measurement in food and beverage applications. Highlighting hygienic design, various connections for sanitary process environments, stable and precise measurements which are suitable for dairies, filling lines, breweries and other F&B processes.

Fields of application: Food and Beverage

Razstavni prostor A-301A

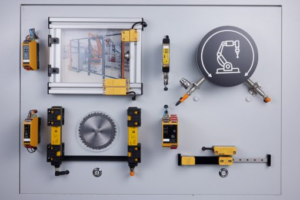

Celoten spekter sodobne zaščite strojev: svetlobne zavese, varnostna stikala, releji in senzorji položaja delujejo skupaj, da ponazorijo, kako lahko proizvodnja ostane hitra in varna. Predstavitev jasno prikazuje, kako so zgrajeni varnostni tokokrogi, kako se sprožijo zaščitne funkcije in kako lahko stroji dosežejo višjo raven zmogljivosti, hkrati pa izpolnjujejo zahtevne standarde PL in SIL. Preprost in prepričljiv način za razumevanje vloge varnosti v današnjih avtomatiziranih tovarnah.

Področja uporabe: splošna avtomatizacija tovarn

Booth A-301A

A full spectrum of modern machine protection: light curtains, safety switches, relays and position sensors work together to illustrate how production can remain both fast and safe. The demonstrator clearly shows how safety circuits are built, how protective functions are triggered and how machines can achieve higher performance levels while still meeting demanding PL and SIL standards. A straightforward and compelling way to understand the role of safety in today’s automated factories.

Fields of application: General Factory Automation

Razstavni prostor A-301A

Solution Block (Multiprotocol Gateway) prikazuje, kako senzorji brezhibno komunicirajo prek več industrijskih protokolov, kot so MQTT, JSON in OPC UA. Prikazuje, kako se lahko različni signali združijo v enoten digitalni tok podatkov – idealno za podjetja, ki uvajajo digitalizacijo v mešanih okoljih opreme.

Področja uporabe: splošna avtomatizacija, avtomobilska industrija

Booth A-301A

Solution Block (Multiprotocol Gateway) shows how sensors can seamlessly communicate via multiple industrial protocols such as MQTT, JSON and OPC UA. It demonstrates how different signals can be merged into a unified digital data flow – ideal for companies implementing digitalization across mixed equipment environments.

Fields of application: General Factory Automation, Automotive